Page 127 - 《摩擦学学报》2021年第5期

P. 127

716 摩 擦 学 学 报 第 41 卷

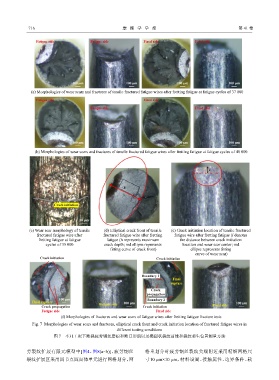

Fatigue side Fatigue side Fixed side Fixed side

100 μm 100 μm 100 μm 100 μm

(a) Morphologies of wear scars and fractures of tensile fractured fatigue wires after fretting fatigue at fatigue cycles of 37 000

Fatigue side Fixed side

Fatigue side Fixed side

100 μm 100 μm 100 μm 100 μm

(b) Morphologies of wear scars and fractures of tensile fractured fatigue wires after fretting fatigue at fatigue cycles of 40 000

l

h

Crack initiation

50 μm

(c) Wear scar morphology of tensile (d) Elliptical crack front of tensile (e) Crack initiation location of tensile fractured

fractured fatigue wire after fractured fatigue wire after fretting fatigue wire after fretting fatigue (l denotes

fretting fatigue at fatigue fatigue (h represents maximum the distance between crack initiation

cycles of 35 000 crack depth; red ellipse represents location and wear scar center; red

fitting curve of crack front) ellipse represents fitting

curve of wear scar)

Crack initiation Crack initiation

Boundary 1

Final

rupture

Crack

propagation

100 μm Boundary 2

Final rupture 100 μm 100 μm

Fatigue side Fixed side

Crack propagation Crack initiation

Fatigue side Fixed side

(f) Morphologies of fractures and wear scars of fatigue wires after fretting fatigue fracture tests

Fig. 7 Morphologies of wear scars and fractures, elliptical crack front and crack initiation location of fractured fatigue wires in

different testing conditions

图 7 不同工况下断裂疲劳钢丝磨痕和断口形貌以及椭圆状裂纹前缘和裂纹萌生位置测量方法

劳裂纹扩展有限元模型中[图4、图8(a~b)],疲劳钢丝 格重划分时疲劳钢丝裂纹尖端附近采用精细网格尺

裂纹扩展区采用四节点四面体单元进行网格划分,网 寸10 μm×10 μm,材料设置、接触属性、边界条件、载