Page 20 - 摩擦学学报2025年第4期

P. 20

508 摩擦学学报(中英文) 第 45 卷

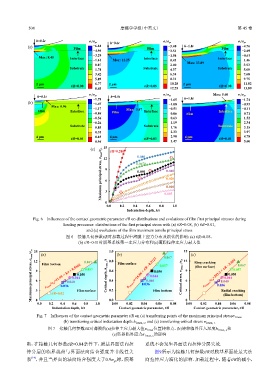

h=0.2t σ 1 /σ ys h=0.6t σ 1 /σ ys σ 1 /σ ys

(a) Film −6.64 Film −5.48 h=1.0t Film −4.76

−2.69

−4.96

−3.51

Max: 8.45 Interface −3.29 Max: 12.25 Interface −1.54 Interface −0.61

0.43

1.46

−1.61

0.07 2.40 Max: 13.89 3.53

Substrate 1.74 Substrate 4.37 Substrate 5.60

3.42 6.34 7.68

5.09 8.31 9.75

2 μm t/R=0.08 6.77 2 μm t/R=0.08 10.28 2 μm t/R=0.08 11.82

8.45 12.25 13.89

Max: 5.60

h=0.1t σ 1 /σ ys h=0.5t σ 1 /σ ys h=1.0t σ 1 /σ ys

−1.78

(b) −1.47 −1.65 −1.74

−1.08

−0.93

Max: 0.96 −1.17

Film Interface −0.86 Film Max: 3.47 Interface −0.51 Film Interface −0.11

0.06

0.71

−0.56 0.63 1.52

−0.26 1.19 2.34

Substrate 0.05 Substrate 1.76 Substrate 3.15

0.35 2.33 3.97

4 μm t/R=0.01 0.65 4 μm t/R=0.01 2.90 4 μm t/R=0.01 4.78

0.96 3.47 5.60

(c) 15 t/R=0.200 0.080

Maximum principal stress, σ 1max /σ ys 9 6 0.0670 0.040

12

0.050

0.020

0.010

0 3 0.005

0.0 0.2 0.4 0.6 0.8 1.0

Indentation depth, h/t

Fig. 6 Influences of the contact geometric parameter t/R on distributions and evolutions of film first principal stresses during

loading processes: distributions of the first principal stress with (a) t/R=0.08, (b) t/R=0.01,

and (c) evolutions of the film maximum tensile principal stress

图 6 接触几何参数t/R对加载过程中薄膜主应力分布及演化的影响:(a) t/R=0.08,

(b) t/R=0.01时膜基系统第一主应力分布和(c)薄膜拉伸主应力最大值

15 (a) 0.067 1.0 (b) 0.067 15 (c) Ring cracking

Maximum principal stress, σ 1max /σ ys 9 6 Film bottom 0.036 0.040 0.050 0.057 Critical depth, h 1max, c /t 0.6 Film surface 0.036 0.044 0.057 Critical stress, σ 1max, c /σ ys 9 6 3 (film surface) 0.036 0.044 0.057

h 1max, c /t=16.86 × t/R - 0.2123

σ 1max, c /σ ys =203.3 × t/R - 2.054

0.8

12

12

σ 1max /σ ys =11.95 × h/t + 0.5642

0.067

0.050

0.050

0.044

0.040

0.4

0.040

0.2

3

(film bottom)

0

0.0 0.2 t/R=0.02 0.6 Film surface 1.0 0.0 0.00 0.02 0.04 Film bottom 0 0.00 0.02 0.04 Radial cracking 0.08

0.4

0.06

0.8

0.06

0.08

Indentation depth, h/t Contact geometric parameter, t/R Contact geometric parameter, t/R

Fig. 7 Influences of the contact geometric parameter t/R on (a) transferring points of the maximum principal stressσ 1max ,

(b) transferring critical indentation depth h 1max, c , and (c) transferring critical stress σ 1max, c

图 7 接触几何参数t/R对薄膜的(a)拉伸主应力最大值σ 1max 位置转移点,(b)转移临界压入深度h 1max, c 和

(c)转移临界应力σ 1max, c 的影响

断,在接触几何参数t/R=0.04条件下,膜基界面法向拉 系统不会发生界面法向拉伸分层失效.

伸分层的临界载荷与界面法向结合强度并非线性关 图9所示为接触几何参数t/R对膜基界面处最大法

[14]

系 ,并且当界面的法向结合强度大于0.9σ 时,膜基 向拉伸应力演化的影响. 加载过程中,随着t/R的减小,

ys