Page 135 - 摩擦学学报2025年第4期

P. 135

第 4 期 赵祥, 等: 非接触式机械密封动特性中的辅助密封研究进展 623

damping of the secondary seal were related to parameters such as sealing pressure and speed. However, they were

expressed as constant values in the dynamic model, ignoring the influence of the change of working conditions, which

was not consistent with the actual working condition. In addition, the effects of rubber aging problems were not

considered. It was not conducive to study the following performance of the compensation ring. The main purpose of the

optimization of the secondary seals was to reduce the friction damping and improve the dynamic performance of the seal

system, which was mainly carried out in terms of the secondary seal structures, the mounting grooves, and the

parameters of the tribological characteristics. Small compression ratio, good lubrication, and the right materials could

reduce friction damping. In summary, the researches on each part of the secondary seals were relatively independent, and

the nonlinear characteristics of material, friction and stiffness and damping were not sufficiently considered in the

studies of the dynamic characteristics of the seal systems. In the future, the researches on secondary seals could focus on

the ontological relationships and the nonlinearities of the friction, stiffness and damping.

Key words: secondary seal; contact characteristic; friction characteristic; dynamic characteristic; mechanical seal

非接触式机械密封通常依靠旋转环和补偿环之 扰动频率等更严苛的水润滑环境中,机械密封同样存

[17]

间的流体动静压效应形成一定厚度的流体膜来避免 在着因辅助密封产生的动特性差和卡滞问题 . 总体

[11]

端面的直接接触,如图1所示,常用于高压和高速等场 而言,辅助密封的研究尚不充分 ,成为制约补偿环

[1] [12]

合. 良好的动特性是保证主密封非接触运行的关键 . 动特性研究的关键,引起较多的失效问题 .

在复杂多变的外界载荷激励下,机械密封旋转环会随 本文中归纳总结了影响非接触式机械密封动特

转子系统产生在轴向和角向的振动,补偿环需要及时 性的辅助密封的关键参数,梳理了辅助密封与插入件

地追随旋转环并保持一定厚度的流体膜 [2-3] . 机械密封 之间接触、摩擦及其自身刚度阻尼等研究历程和不

动特性差会导致流体膜厚度偏离适宜区间甚至端面 足,总结了以提高动特性为目标的辅助密封研究关键

[4]

接触,在高速高压环境中引起密封泄漏过大 或磨损 和热点问题,为进一步开展相关研究提供了思路.

失效 [5-7] . 机械密封中的辅助密封是影响其动特性的关

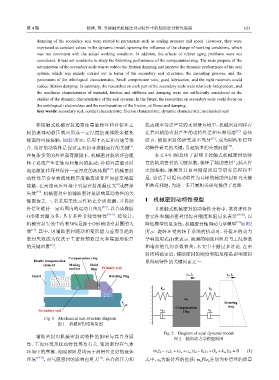

键因素之一,常采用柔性元件防止介质泄漏,并协助 1 机械密封动特性模型

补偿环维持一定范围内的运动自由度 [8-9] ,以合成橡胶 非接触式机械密封的动特性分析中,常将弹性补

O形密封圈为多,具有多种非线性特性 [10-11] . 经统计, 偿元件和辅助密封用综合刚度和阻尼来表示 [18-20] ,以

[21]

机械密封失效中约有30%是源于O形辅助密封圈的失 降低模型的复杂性,机械密封轴向动力学模型 如图2

[12]

效 . 其中,因辅助密封随动和变形能力差而引起的 所示. 旋转环受到转子系统的扰动时,补偿环的动力

密封失效成为仅次于主密封预紧过大和端面形貌差 学响应用式(1)来表示. 液膜的刚度和阻尼与工况参数

[13]

的关键因素 . 和端面的几何参数有关,本文中不做过多讨论. 在密

封结构确定后,辅助密封的刚度和阻尼便是影响密封

Elastic compensation Compensation ring 系统动特性的关键因素之一.

element Mating Fluid

surface film Primary seal

·

·

Insert Rotating ring z 2 , z 2 z 1 , z 1

k SO k Z

m S

ω Compensation Rotating

ring

Secondary seal c SO ring c Z

Fig. 1 Mechanical seal structure diagram

图 1 机械密封结构简图

Fig. 2 Diagram of axial dynamic model

辅助密封对机械密封动特性的影响与其自身属 图 2 轴向动力学模型简图

性、工况环境及扰动特性等均有关. 辅助密封在气体

环境中的摩擦、刚度和阻尼均高于润滑性更好的液体 m s ¨z 2 −c z ˙z 1 +(c z +c so ) ˙z 2 −k z z 1 +(k z +k so )z 2 = 0 (1)

[16]

环境 [14-15] ,对气膜密封的影响也更大 . 在介质压力和 式中,z 为旋转环的位移;m 和z 分别为补偿环的质量

1

2

s