Page 130 - 《摩擦学学报》2021年第2期

P. 130

第 2 期 尹兆明, 等: 基于热弹流润滑的双渐开线齿轮温度场研究 275

B: Steacly-state thermal B: Steacly-state thermal

Temperature Temperature

Type: temperature Type: temperature

Unit: ℃ Unit: ℃

Time: 1 Time: 1

2020/4/12 22:02 2020/4/12 22:03

88.474 Max 88.474 Max

87.124 87.124

85.773 85.773

84.423 84.423

83.073 83.073

81.722 81.722

80.372 80.372

79.021 79.021

77.671 77.671

76.321 Min 0.000 0.010 0.020 m 76.321 Min 0.000 0.010 0.020 m

(a) Bluk temperature of driving gear (b) Bluk temperature of driven gear

∗

∗

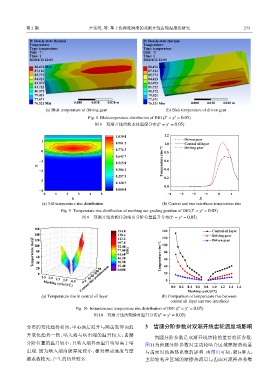

Fig. 8 Bluktemperature distribution of DIG ( l = y = 0.05)

∗

∗

图 8 双渐开线齿轮本体温度分布( l = y = 0.05)

1.2

1.030 0

1 0.901 2 1.0 Driven gear

Central oil layer

0.772 5 Driving gear

0 0.8

0.643 7

−1 Temperature rise/℃ 0.6

0.515 0

X

−2 0.386 2 0.4

0.257 5 0.2

−3

0.128 7

0.0

−4 0.000 0

0 1 2 3 4 5 −4 −3 −2 −1 0 1

h X

(a) 3-D temperature rise distribution (b) Central and two interfaces temperature rise

Fig. 9 Temperature rise distribution of meshing out grading position of DIG( l = y = 0.05)

∗

∗

∗

∗

图 9 双渐开线齿轮传动啮出分阶位置温升分布( l = y = 0.05)

160

154.0 140 Central oil layer

140 138.6 120 Driving gear

Temperature rise/K 100 92.40 DIG Temperature rise/℃ 100

123.2

Driven gear

120

107.8

77.00

80

80

61.60

60

46.20

60

40

15.40

20 40 50 30.80 40

0.000

0 20 30 20

2.5 2.0 Contact line position/mm

10

1.5 1.0 0

0.5 0 0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Meshing cycle/(t/T c )

Meshing cycle/(t/T c )

(a) Temperature rise in central oil layer (b) Comparison of temperature rise between

central oil layer and two interfaces

∗

∗

Fig. 10 Instantaneous temperature rise distribution of DIG ( l = y = 0.05)

∗

∗

图 10 双渐开线齿轮瞬时温升分布( l = y = 0.05)

分布的变化趋势相同;中心油层温升与两齿轮界面温 3 齿腰分阶参数对双渐开线齿轮温度场影响

升变化趋势一致,啮入端与啮出端的温升较大,齿腰

齿腰分阶参数是双渐开线齿轮的重要特征参数.

分阶位置的温升较小,且啮入端界面温升明显高于啮 图11为齿腰分阶参数对主动轮啮合区域摩擦热流量

出端. 因为啮入端油膜厚度较小,相对滑动速度与摩 与齿面对流换热系数的影响. 由图11可知,随 l∗增大,

擦系数较大,产生的热量较多. 主动轮啮合区域的摩擦热流量与齿面对流换热系数