Page 92 - 《摩擦学学报》2020年第3期

P. 92

358 摩 擦 学 学 报 第 40 卷

0.45

40

20

0.40 0

Friction coefficient 0.30 Wear depth/μm −20 −63.6

0.35

−40

−60

−80

0.25

A1 (022Cr12Ni9Cu2NbTi/TC4) −100 −73.6 022Cr12Ni9Cu2NbTi/TC4

0.20 A2 (1Cr18Ni9Ti/TC4) −120 1Cr18Ni9Ti/TC4

100 A3 (90Cr18MoV/TC4) 90Cr18MoV/TC4

−140

0.15

0 500 1 000 1 500 2 000 2 500 3 000 3 500 0 1 2 3 4

Time/s Lateral/mm

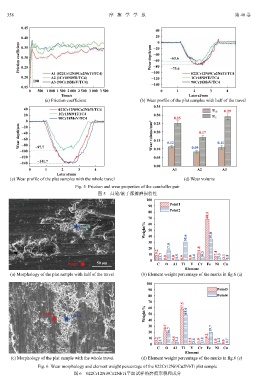

(a) Friction coefficient (b) Wear profile of the plat samples with half of the travel

0.35

40 022Cr12Ni9Cu2NbTi/TC4

N C2 0.29

1Cr18Ni9Ti/TC4

20 0.30

90Cr18MoV/TC4 0.25 N C

0 0.25

Wear depth/μm −40 Wear volume/mm 3 0.20 0.12 0.17 0.11

−20

−60

0.15

−80

−100 −97.7 0.10 0.09

−120 0.05

−140 −141.7

0.00

0 1 2 3 4 A1 A2 A3

Lateral/mm

(c) Wear profile of the plat samples with the whole travel (d) Wear volume

Fig. 5 Friction and wear properties of the cam/roller pair

图 5 凸轮/滚子摩擦磨损特性

100

Point1

90

Point2

80

70 68.1

Weight/% 50 35.0

Point2 60

40

30 30.6

20 17.0 11.8

9.2

10 3.7 0.0 0.0 1.5 0.9 0.0 1.6 6.5 7.4 3.3 2.1 0.8

50 μm 0

Point1 C O Al Ti V Cr Fe Ni Cu

Element

(a) Morphology of the plat sample with half of the travel (b) Element weight percentage of the marks in fig.6 (a)

100

90 Point3

80 Point4

70 57.5

Weight/%

50

Point3 60 48.6

Point4 40

30 20.7 19.7

20 16.7

10 4.4 9.2

3.2 3.7 3.2 2.5 2.1 1.5 3.1 1.0 2.2 0.7

0 0.0

50 μm C O Al Ti V Cr Fe Ni Cu

Element

(c) Morphology of the plat sample with the whole travel (d) Element weight percentage of the marks in fig.6 (c)

Fig. 6 Wear morphology and element weight percentage of the 022Cr12Ni9Cu2NbTi plat sample

图 6 022Cr12Ni9Cu2NbTi平面试样的磨痕形貌和成分