Page 80 - 摩擦学学报2025年第4期

P. 80

568 摩擦学学报(中英文) 第 45 卷

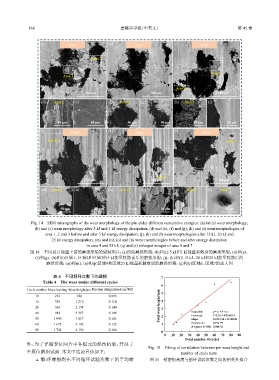

(a) 0 kJ (b) 5 kJ (c) 10 kJ

Area 2

Area 3

Area 1

Area 4

300 μm 300 μm 300 μm

(d) Area 1 (e) (f) Area 2 (g) (h) Area 3 (i)

50 μm 50 μm 50 μm 50 μm 50 μm 50 μm

(j) 15 kJ (k) 20 kJ (l) 25 kJ

Area 5 Area 7

Area 6

300 μm 300 μm 300 μm

(m) Area 4 (n) (o) Area 5 (p) (q) Area 6 (r) Area 7

50 μm 50 μm 50 μm 50 μm 50 μm 50 μm

Fig. 14 SEM micrographs of the wear morphology of the pin under different cumulative energies: (a) initial wear morphology;

(b) and (c) wear morphology after 5 kJ and 1 kJ energy dissipation; (d) and (e), (f) and (g), (h) and (i) wear morphologies of

area 1, 2 and 3 before and after 5 kJ energy dissipation; (j), (k) and (l) wear morphologies after 15 kJ, 20 kJ and

25 kJ energy dissipation; (m) and (n), (o) and (p) wear morphologies before and after energy dissipation

in area 4 and 55 kJ; (q) and (r) enlarged images of area 6 and 7

图 14 不同累计能量下销的磨损形貌的SEM照片:(a)初始磨损形貌;(b)和(c) 5 kJ和1 kJ能量耗散后的磨损形貌;(d)和(e)、

(f)和(g)、(h)和(i)区域1、区域2和区域3的5 kJ能量耗散前后的磨损形貌;(j)、(k)和(l) 15 kJ、20 kJ和25 kJ能量耗散后的

磨损形貌;(m)和(n)、(o)和(p)区域4和区域55 kJ能量耗散前后的磨损形貌;(q)和(r)区域6、区域7的放大图

表 4 不同循环次数下的磨损 7

Table 4 The wear under different cycles

6

3

Cycle number Mass loss/mg Wear height/μm Friction dissipation/(cm /MJ) 5

10 252 926 0.093

14 330 1 210 0.114 4

20 592 2 174 0.140 Total wear height/mm 3

40 914 3 357 0.108 2 Equation y = a + b × x

Intercept

213.25 ± 402.652 5

50 1 040 3 817 0.101 Slope 82.223 54 ± 8.758 05

60 1 672 6 142 0.132 1 Pearson′s r 0.972 79

R square (COD) 0.946 32

80 1 742 6 396 0.106

0

0 10 20 30 40 50 60 70 80 90

Total number of cycles

外,为了详细表征闸片中各组元的损伤机制,开展了

Fig. 15 Fitting of correlation between pin wear height and

半原位磨损试验. 本文中结论具体如下: number of cycle tests

a. 销-环摩擦副在不同循环试验次数下的平均摩 图 15 销磨损高度与循环试验次数之间的相关性拟合