Page 95 - 《摩擦学学报》2021年第4期

P. 95

538 摩 擦 学 学 报 第 41 卷

24 24 24

Contact pressure/MPa 16 8 Contact pressure/MPa 16 8 Contact pressure/MPa 16 8

20

20

20

12

12

12

Without a boss

4

With a boss

With a boss 4 Without a boss 4 Without a boss

With a boss

0 0 0

1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

Contact position/mm Contact position/mm Contact position/mm

(a) ε=3% (b) ε=5% (c) ε=7%

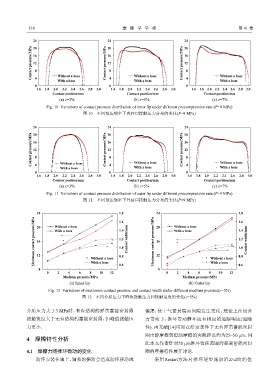

Fig. 10 Variations of contact pressure distribution of inner lip under different precompression rate (P=9 MPa)

图 10 不同预压缩率下内唇口接触压力分布的变化(P=9 MPa)

24 24 24

Contact pressure/MPa 16 8 Contact pressure/MPa 16 8 Contact pressure/MPa 16 8

20

20

20

12

12

12

Without a boss

4

With a boss

With a boss

With a boss 4 Without a boss 4 Without a boss

0 0 0

1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

Contact position/mm Contact position/mm Contact position/mm

(a) ε=3% (b) ε=5% (c) ε=7%

Fig. 11 Variations of contact pressure distribution of outer lip under different precompression rate (P=9 MPa)

图 11 不同预压缩率下外唇口接触压力分布的变化(P=9 MPa)

24 Without a boss 1.8 24 Without a boss 1.8

Maximum contact pressure/MPa 16 With a boss 1.4 Contact width/mm Maximum contact pressure/MPa 16 With a boss 1.4 Contact width/mm

1.6

1.6

20

20

1.2

1.2

1.0

1.0

12

12

With a boss

With a boss

0.6

0.6

8 Without a boss 0.8 8 Without a boss 0.8

0 2 4 6 8 10 12 0 2 4 6 8 10 12

Medium pressure/MPa Medium pressure/MPa

(a) Inner lip (b) Outer lip

Fig. 12 Variations of maximum contact pressure and contact width under different medium pressure(ε=5%)

图 12 不同介质压力下峰值接触压力和接触宽度的变化(ε=5%)

介质压力大于3 MPa时,有台结构的弹簧蓄能密封圈 偏摆,使干气密封端面间隙发生变化,理论上在闭合

接触宽度大于无台结构的蓄能密封圈,但峰值接触压 力带动下,推环带动静环应有相应的追踪响应(追随

力更小. 性). 由文献[14]可知在给定条件下无台弹簧蓄能密封

圈由静摩擦到滑动摩擦的突跳距离约为25~50 μm,因

4 摩擦特性分析

此本文作者针对50 μm推环位移范围的弹簧蓄能密封

4.1 摩擦力随推环微动的变化 圈的摩擦特性展开讨论.

动环安装在轴上,轴系的振动会造成动环移动或 采用Restart方法对推环逐步施加沿Z/-Z向的位