Page 98 - 《摩擦学学报》2020年第5期

P. 98

第 5 期 吴可欣, 等: 阻旋栅对梳齿密封动静特性影响研究 653

16 8

n=0, λ=0.36 4 No brake

n=90, λ=0.36

Circumferential velocity/(m/s) 10 8 6 4 n=0, λ=0.81 Cross-coupled stiffness/(10 3 N/m) −4 0

14

s=0.25

n=0, λ=0.51

s=0.20

n=90, λ=0.51

12

s=0.15

n=90, λ=0.81

0 2 −8

30 31 32 33 34 0 50 100 150 200 250 300

Position/mm Whirling frequency/Hz

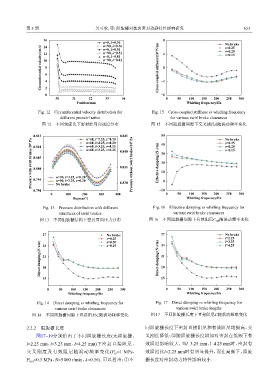

Fig. 12 Circumferential velocity distribution for Fig. 15 Cross-coupled stiffness vs whirling frequency

different preswirl ratios for various swirl brake clearances

图 12 不同预旋比下密封腔周向速度分布 图 15 不同阻旋栅间隙下交叉刚度k随涡动频率变化

8.815 n=60, l=2.25, s=0.20 8.845 50 No brake

Pressure with swirl brakes/10 5 Pa 8.805 n=30, l=3.25, s=0.20 n=60, l=3.25, s=0.25 8.840 Pressure without swirl brakes/10 5 Pa Effective damping/(N·s/m) 30

n=60, l=4.25, s=0.20

s=0.25

40

n=60, l=3.25, s=0.15

8.810

s=0.20

s=0.15

20

8.835

8.800

10

8.795

No brake

8.790 n=90, l=3.25, s=0.20 8.830 −10 0

0 100 200 300 400 0 50 100 150 200 250 300

Degree/(°) Whirling frequency/Hz

Fig. 13 Pressure distribution with different Fig. 16 Effective damping vs whirling frequency for

structures of swirl brakes various swirl brake clearances

图 13 不同阻旋栅结构下密封周向压力分布 图 16 不同阻旋栅间隙下有效阻尼C eff 随涡动频率变化

27 No brake 27 No brake

s=0.25 24 l=2.25

l=3.25

Direct damping/(N·s/m) 21 Direct damping/(N·s/m) 21

s=0.20

l=4.25

24

s=0.15

18

18

15 15

0 50 100 150 200 250 300 0 50 100 150 200 250 300

Whirling frequency/Hz Whirling frequency/Hz

Fig. 14 Direct damping vs whirling frequency for Fig. 17 Direct damping vs whirling frequency for

various swirl brake clearances various swirl brake lengths

图 14 不同阻旋栅间隙下直接阻尼C随涡动频率变化 图 17 不同阻旋栅长度下直接阻尼C随涡动频率变化

2.2.2 阻旋栅长度 同阻旋栅长度下密封直接阻尼和有效阻尼均提高,交

图17~19分别给出了不同阻旋栅长度(无阻旋栅、 叉刚度降低;②随阻旋栅长度增加对密封在低频下有

l=2.25 mm、l=3.25 mm、l=4.25 mm)下密封直接阻尼、 效阻尼影响较大,当l=3.25 mm、l=4.25 mm时,密封有

交叉刚度及有效阻尼随涡动频率变化(P =1 MPa、 效阻尼比l=2.25 mm时有明显提升,而在高频下,阻旋

in

P =0.3 MPa、N=5000 r/min、 λ=0.36). 可以看出:①不 栅长度对密封动力特性影响较小.

out