Page 13 - 《摩擦学学报》2021年第2期

P. 13

158 摩 擦 学 学 报 第 41 卷

(b) (c)

0.18 (a)

0.16

0.14

Friction coefficient 0.10 (d) 20 μm (e) 20 μm

0.12

0.08

0.06

0.04

IRIS

0.02 IRIS+0.05%ODA-GO

0.00

0 5 000 10 000 15 000 20 000 2 μm 2 μm

Number of cycles

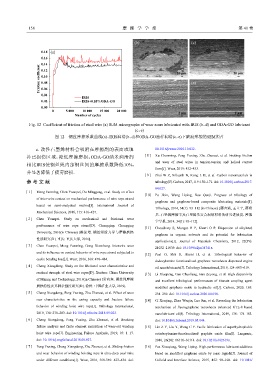

Fig. 12 Coefficient of friction of steel wire (a) SEM micrographs of wear scars lubricated with IRIS (b,d) and ODA-GO lubricant

(c,e)

图 12 钢丝摩擦系数曲线(a)、IRIS润滑(b,d)和ODA-GO油样润滑(c,e)下磨痕形貌的SEM照片

c. 改性石墨烯材料会吸附在摩擦副的表面或填 10.1016/j.wear.2016.10.012.

补已损伤区域,降低摩擦磨损;ODA-GO纳米润滑剂 [ 8 ] Xu Chunming, Peng Yuxing, Zhu Zhencai, et al. Fretting friction

and wear of steel wires in tension-torsion and helical contact

相比IRIS使钢丝绳内部钢丝间的摩擦系数降低10%,

form[J]. Wear, 2019: 432–433.

并显著降低了疲劳磨损.

[ 9 ] Zhai W Z, Srikanth N, Kong L B, et al. Carbon nanomaterials in

参 考 文 献 tribology[J]. Carbon, 2017, 119: 150–171. doi: 10.1016/j.carbon.2017.

04.027.

[ 1 ] Meng Fanming, Chen Yuanpei, Du Minggang, et al. Study on effect

[10] Pu Jibin, Wang Liping, Xue Qunji. Progress of tribology of

of inter-wire contact on mechanical performance of wire rope strand

graphene and graphene-based composite lubricating materials[J].

based on semi-analytical method[J]. Internaional Journal of

Tribology, 2014, 34(1): 93–112 (in Chinese) [蒲吉斌, 王立平, 薛群

Mechanical Sciences, 2016, 115: 416–427.

基. 石墨烯摩擦学及石墨烯基复合润滑材料的研究进展[J]. 摩擦

[ 2 ] Chen Yuanpei. Study on mechanical and frictional wear

学学报, 2014, 34(1): 93–112].

performance of wire rope strand[D]. Chongqing: Chongqing

[11] Choudhary S, Mungse H P, Khatri O P. Dispersion of alkylated

University, 2016(in Chinese) [陈原培. 钢丝绳股力学与摩擦磨损

graphene in organic solvents and its potential for lubrication

性能研究[D]. 重庆: 重庆大学, 2016].

applications[J]. Journal of Materials Chemistry, 2012, 22(39):

[ 3 ] Chen Yuanpei, Meng Fanming, Gong Xiansheng. Interwire wear

21032–21039. doi: 10.1039/c2jm34741e.

and its influence on contact behavior of wire rope strand subjected to

[12] Paul G, Shit S, Hirani H, et al. Tribological behavior of

cyclic bending load[J]. Wear, 2016, 368: 470–484.

dodecylamine functionalized graphene nanosheets dispersed engine

[ 4 ] Chang Xiangdong. Study on the frictional wear characteristics and

oil nanolubricants[J]. Tribology International, 2019, 124: 605–619.

residual strength of steel wire ropes[D]. Xuzhou: China University

[13] Li Xiaopeng, Gan Chaoliang, Han Zeyong, et al. High dispersivity

of Mining and Technology, 2019(in Chinese) [常向东. 钢丝绳摩擦

and excellent tribological performances of titanate coupling agent

磨损特性及其剩余强度研究[D]. 徐州: 中国矿业大学, 2019].

modified graphene oxide in hydraulic oil[J]. Carbon, 2020, 165:

[ 5 ] Chang Xiangdong, Peng Yuxing, Zhu Zhencai, et al. Effect of wear 238–250. doi: 10.1016/j.carbon.2020.04.038.

scar characteristics on the earing capacity and fracture failure [14] Ci Xiaojing, Zhao Wenjie, Luo Jun, et al. Revealing the lubrication

behavior of winding hoist wire rope[J]. Tribology International, mechanism of fluorographene nanosheets enhanced GTL-8 based

2019, 130: 270–283. doi: 10.1016/j.triboint.2018.09.023. nanolubricant oil[J]. Tribology International, 2019, 138: 174–183.

[ 6 ] Chang Xiangdong, Peng Yuxing, Zhu Zhencai, et al. Breaking doi: 10.1016/j.triboint.2019.05.044.

failure analysis and finite element simulation of wear-out winding [15] Lin Z Y, Liu Y, Wong C P. Facile fabrication of superhydrophobic

hoist wire rope[J]. Engineering Failure Analysis, 2019, 95: 1–17. octadecylamine-functionalized graphite oxide film[J]. Langmuir,

doi: 10.1016/j.engfailanal.2018.08.027. 2010, 26(20): 16110–16114. doi: 10.1021/la102619n.

[ 7 ] Peng Yuxing, Chang Xiangdong, Zhu Zhencai, et al. Sliding friction [16] Fan Xiaoqiang, Wang Liping. High-performance lubricant additives

and wear behavior of winding hoisting rope in ultra-deep coal mine based on modified graphene oxide by ionic liquids[J]. Journal of

under different conditions[J]. Wear, 2016, 368-369: 423–434. doi: Colloid and Interface Science, 2015, 452: 98–108. doi: 10.1016/