Page 22 - 《摩擦学学报》2020年第4期

P. 22

432 摩 擦 学 学 报 第 40 卷

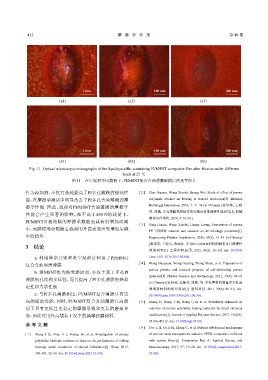

1 mm 100 mm 200 mm

(a1) (a2) (a3)

1 mm 100 mm 200 mm

(b1) (b2) (b3)

Fig. 11 Optical microscopic micrographs of the liquid paraffin-containing PI/MSNT composite film after friction under different

loads at 25 ℃

图 11 在室温和不同载荷下,PI/MSNT复合含油薄膜摩擦后的光学照片

作为添加剂,不仅有效地提高了PI多孔薄膜的储油性 [ 2 ] Zhao Huajun, Wang Xiaolei, Huang Wei. Study of effect of porous

能,在摩擦学测试中明显改善了PI多孔含油薄膜的摩 polyimide retainer on bearing at starved lubrication[J]. Machine

擦学性能. 因此,载荷对PI/MSNT含油薄膜的摩擦学 Building&Automation, 2018, 3: 31–34 (in Chinese) [赵华俊, 王晓

雷, 黄巍. 多孔聚酰亚胺保持架对轴承贫油润滑性能研究[J]. 机械

性能会产生显著的影响,在不高于450 N的载荷下,

制造与自动化, 2018, 3: 31–34].

PI/MSNT含油薄膜的摩擦系数随着载荷的增加而减

[ 3 ] Tang Huixia, Wang Xiaolei, Huang Lirong. Preparation of porous

小,而磨损寿命则随着载荷的升高表现出先增加后减

PE –UHMW material and research on its tribology properties[J].

少的趋势. Engineering Plastics Application, 2015, 43(2): 16–19 (in Chinese)

[唐慧霞, 王晓雷, 黄丽容. 多孔PE-UHMW材料的制备及其摩擦性

3 结论

能的研究[J]. 工程塑料应用, 2015, 43(2): 16–19]. doi: 10.3969/

a. 利用掺杂共聚和真空浸油法制备了PI/MSNT j.issn.1001-3539.2015.02.004.

[ 4 ] Wang Huaiyuan, Wang Guiying, Zhang Shuai, et al. Preparation of

复合含油润滑薄膜.

porous plastics and research progress of self-lubricating porous

b. 将MSNT作为纳米添加剂,不仅丰富了多孔PI

materials[J]. Plastics Science and Technology, 2011, 39(6): 88–91

薄膜的孔结构多样性,而且提高了PI多孔薄膜的热稳

(in Chinese) [汪怀远, 汪桂英, 张帅, 等. 多孔塑料的制备及多孔自

定性和力学性能.

润滑新材料的研究进展[J]. 塑料科技, 2011, 39(6): 88–91]. doi:

c. 与PI多孔薄膜相比,PI/MSNT复合薄膜具有更 10.3969/j.issn.1005-3360.2011.06.016.

高的储油性能;同时,PI/MSNT复合含油薄膜在高载 [ 5 ] Zhang D, Wang T M, Wang Q H, et al. Selectively enhanced oil

荷下具有更低且更稳定的摩擦系数和更长的磨损寿 retention of porous polyimide bearing materials by direct chemical

命,因此可用作高载荷工况下的减摩抗磨材料. modification[J]. Journal of Applied Polymer Science, 2017, 134(29):

45106–45112. doi: 10.1002/app.45106.

参 考 文 献

[ 6 ] Guo L H, Qi H M, Zhang G, et al. Distinct tribological mechanisms

[ 1 ] Wang J Q, Zhao H J, Huang W, et al. Investigation of porous of various oxide nanoparticles added in PEEK composite reinforced

polyimide lubricant retainers to improve the performance of rolling with carbon fibers[J]. Composites Part A: Applied Science and

bearings under conditions of starved lubrication[J]. Wear, 2017, Manufacturing, 2017, 97: 19–30. doi: 10.1016/j.compositesa.2017.

380-381: 52–58. doi: 10.1016/j.wear.2017.03.008. 03.003.