Page 102 - 《摩擦学学报》2021年第6期

P. 102

第 6 期 李正阳, 等: 工作电压对N36锆合金表面微弧氧化涂层磨蚀性能的影响 887

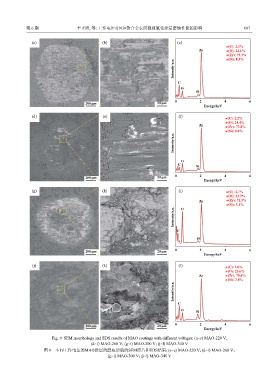

(a) (b) (c)

w(C): 2.1%

Zr w(O): 22.1%

w(Zr): 75.3%

w(Si): 0.5%

Intensity/a.u.

C

O

Si

200 μm 20 μm 0 2 4 6

Energy/keV

(d) (e) (f)

w(C): 2.2%

w(O): 24.4%

Zr

w(Zr): 72.8%

w(Si): 0.6%

Intensity/a.u.

O

C

Si

200 μm 20 μm 0 2 4 6

Energy/keV

(g) (h) (i) w(C): 2.7%

w(O): 22.9%

Zr w(Zr): 71.3%

w(Si): 3.1%

Intensity/a.u.

O

C

Si

200 μm 20 μm 0 2 4 6

Energy/keV

(j) (k) (l)

w(C): 3.0%

w(O): 23.6%

Zr w(Zr): 70.6%

w(Si): 2.8%

Intensity/a.u.

C

O Si

200 μm 20 μm 0 2 4 6

Energy/keV

Fig. 9 SEM morphology and EDS results of MAO coatings with different voltages: (a~c) MAO-220 V,

(d~f) MAO-260 V; (g~i) MAO-300 V; (j~l) MAO-340 V

图 9 不同工作电压的MAO涂层的磨痕形貌的SEM照片和EDS结果:(a~c) MAO-220 V;(d~f) MAO-260 V;

(g~i) MAO-300 V;(j~l) MAO-340 V