Page 81 - 《摩擦学学报》2020年第6期

P. 81

764 摩 擦 学 学 报 第 40 卷

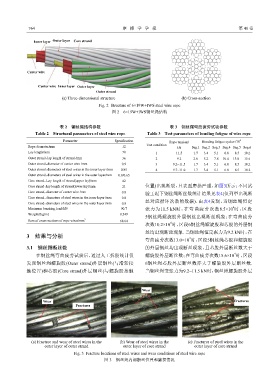

Inner layer Outer layer Core strand

Center wire

Center wire Inner layer Outer layer

Outer strand

(a) Three-dimensional structure (b) Cross-section

Fig. 2 Structure of 6×19W+IWS steel wire rope

图 2 6×19W+IWS钢丝绳结构

表 2 钢丝绳结构参数 表 3 钢丝绳弯曲疲劳试验参数

Table 2 Structural parameters of steel wire rope Table 3 Test parameters of bending fatigue of wire rope

Parameter Specification Rope tension/ Bending fatigue cycles /10 4

Test condition

Rope diameter/mm 12 kN Seg.1 Seg.2 Seg.3 Seg.4 Seg.5 Seg.6

Lay length/mm 78 1 11.5 1.7 3.4 5.1 6.8 8.5 10.2

Outer strand,lay length of strand /mm 36 2 9.2 2.6 5.2 7.8 10.4 13.0 15.6

Outer strand,diameter of center wire /mm 0.9 3 9.2~11.5 1.7 3.4 5.1 6.8 8.5 10.2

Outer strand,diameters of steel wires in the inner layer /mm 0.85 4 9.7~11.0 1.7 3.4 5.1 6.8 8.5 10.2

Outer strand,diameters of steel wires in the outer layer/mm 0.9/0.65

Core strand,Lay length of strand(upper lay)/mm 42

Core strand,lay length of strand(lower lay)/mm 21 位置)出现断裂,且表面磨损严重,如图3所示;不同试

Core strand,diameter of center wire /mm 0.8 验工况下钢丝绳断丝数统计结果见表4(仅列举出现断

Core strand,diameters of steel wires in the inner layer /mm 0.8

丝对应循环次数的数据). 由表4发现,当钢丝绳恒定

Core strand,diameters of steel wires in the outer layer /mm 0.8

4

Minimum breaking load/kN 90.7 张力为11.5 kN时,在弯曲疲劳次数8.5×10 时,区段

Weight/(kg/m) 0.549

5钢丝绳螺旋股外层钢丝出现断丝现象;在弯曲疲劳

2

Sum of cross sections of rope wires/mm 68.64

4

次数10.2×10 时,区段6钢丝绳螺旋股和芯股的外层钢

丝均出现断丝现象. 当钢丝绳恒定张力为9.2 kN时,在

3 结果与分析

4

弯曲疲劳次数13.0×10 时,区段5钢丝绳芯股和螺旋股

3.1 钢丝绳断丝数 的外层钢丝均出现断丝现象,且芯股外层断丝数大于

4

在钢丝绳弯曲疲劳试验后,通过人工拆股统计仅 螺旋股外层断丝数;在弯曲疲劳次数15.6×10 时,区段

发现钢丝绳螺旋股(Outer strand)外层钢丝(与滑轮接 6钢丝绳芯股外层断丝数亦大于螺旋股外层断丝数.

触位置)和芯股(Core strand)外层钢丝(与螺旋股接触 当钢丝绳变张力为9.2~11.5 kN时,钢丝绳螺旋股外层

Wear

Wear Fractures

Fractures

(a) Fracture and wear of steel wires in the (b) Wear of steel wires in the (c) Fractures of steel wires in the

outer layer of outer strand outer layer of core strand outer layer of core strand

Fig. 3 Fracture locations of steel wires and wear conditions of steel wire rope

图 3 钢丝绳内部断丝位置和磨损情况