Page 317 - 《软件学报》2020年第10期

P. 317

孙晓鹏 等:局部各向异性的薄壳收缩变形 3293

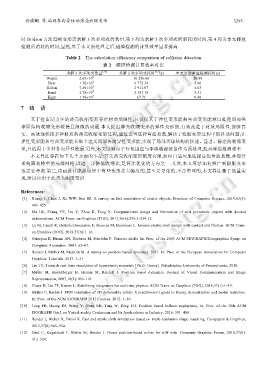

时 Bridson 方法每帧变形需求解 3 次多项式的数量,第 3 列为求解 3 次多项式所消耗的时间,第 4 列为本文碰撞

检测所消耗的时间,显然,基于本文预处理之后,碰撞检测的计算效率显著提高.

Table 2 The calculation efficiency comparison of collision detection

表 2 碰撞检测计算效率对比

求解 3 次多项式数量 [22] 求解 3 次多项式耗时 [22] (s) 本文方法碰撞检测耗时(s)

9

Wapiti 2.69×10 10 256.66 20.88

9

Bear 1.70×10 6 772.54 5.66

8

Kitten 7.49×10 2 911.07 4.63

8

Hand 5.78×10 2 187.18 3.51

7

Eight 1.76×10 67.71 0.48

7 结 语

基于位置动力学的薄壳收缩变形存在材质局限性,且仅仅基于弹性变形能和弯曲变形能难以处理局部类

球面结构收缩变形缓慢且细微的问题.本文提出薄壳收缩变形的弹性变形能,有效改进了材质局限性,能够真

实、高效地模拟多种材质的薄壳收缩变形过程;通过适当选择弯曲系数,解决了收缩变形过程中的抖动问题;在

弹性变形能和弯曲变形能基础上定义局部各向异性变形能,实现了局部类球结构的快速、显著、稳定的收缩变

形,且适用于多种各向异性能量.另外,本文以轴向平行包围盒与非渗透滤波器作为预处理,提高碰撞检测效率.

本文算法存在如下几个方面的不足:首先薄壳收缩变形幅度有限,如何自适应地选择最优弯曲系数,并细分

重构薄壳模型的局部网格,以进一步降低收缩比,是算法优化的方向之一.其次,本文算法如何推广到膨胀变形

也需要考虑.第三,动画设计虚拟场景中有些变形是大幅度的,甚至是夸张的,不合常理的,本文算法基于能量实

现,难以应用于此类大幅度变形.

References:

[1] Huang J, Chen J, Xu WW, Bao HJ. A survey on fast simulation of elastic objects. Frontiers of Computer Science, 2019,13(3):

443–459.

[2] Ma LK, Zhang YZ, Liu Y, Zhou K, Tong X. Computational design and fabrication of soft pneumatic objects with desired

deformations. ACM Trans. on Graphics (TOG), 2017,36(6):239:1–239:12.

[3] Ly M, Casati R, Bertails-Descoubes F, Skouras M, Boissieux L. Inverse elastic shell design with contact and friction. ACM Trans.

on Graphics (TOG), 2018,37(6):1–16.

[4] Grinspun E, Hirani AN, Desbrun M, Schröder P. Discrete shells. In: Proc. of the 2003 ACM SIGGRAPH/Eurographics Symp. on

Computer Animation. 2003. 62–67.

[5] Bender J, Müller M, Macklin M. A survey on position based dynamics, 2017. In: Proc. of the European Association for Computer

Graphics: Tutorials. 2017. 1–31.

[6] Liu TT. Towards real-time simulation of hyperelastic materials [Ph.D. Thesis]. Philadelphia: University of Pennsylvania, 2018.

[7] Müller M, Heidelberger B, Hennix M, Ratcliff J. Position based dynamics. Journal of Visual Communication and Image

Representation, 2007,18(2):109–118.

[8] Dinev D, Liu TT, Kavan L. Stabilizing integrators for real-time physics. ACM Trans. on Graphics (TOG), 2018,37(1):1–19.

[9] Sifakis E, Barbič J. FEM simulation of 3D deformable solids: A practitioner’s guide to theory, discretization and model reduction.

In: Proc. of the ACM SIGGRAPH 2012 Courses. 2012. 1–50.

[10] Tang PB, Huang DJ, Wang Y, Gong RB, Tang W, Ding YD. Position based balloon angioplasty. In: Proc. of the 15th ACM

SIGGRAPH Conf. on Virtual-reality Continuum and Its Applications in Industry. 2016. 391–400.

[11] Bender J, Weber D, Diziol R. Fast and stable cloth simulation based on multi-resolution shape matching. Computers & Graphics,

2013,37(8):945–954.

[12] Deul C, Kugelstadt T, Weiler M, Bender J. Direct position-based solver for stiff rods. Computer Graphics Forum, 2018,37(6):

313–324.