Page 32 - 摩擦学学报2025年第4期

P. 32

520 摩擦学学报(中英文) 第 45 卷

(a) 2 2

0 0

Height/μm −2 Height/μm −2

−4

−4

−6

−8

−8 −6

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0.0 0.2 0.4 0.6 0.8 1.0 1.2

X position/mm Y position/mm

(b) 4 4

2 2

Height/μm −2 0 Height/μm −2 0

−4 −4

−6 −6

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0.0 0.2 0.4 0.6 0.8 1.0 1.2

X position/mm Y position/mm

(c) 4 4

2 2

Height/μm −2 0 Height/μm −2 0

−4

−6

−6 −4

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0.0 0.2 0.4 0.6 0.8 1.0 1.2

X position/mm Y position/mm

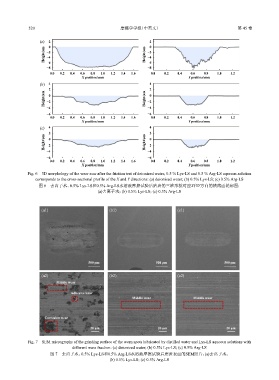

Fig. 6 3D morphology of the wear scar after the friction test of deionized water, 0.5 % Lys-LS and 0.5 % Arg-LS aqueous solution

corresponds to the cross-sectional profile of the X and Y directions: (a) deionized water; (b) 0.5% Lys-LS; (c) 0.5% Arg-LS

图 6 去离子水、0.5% Lys-LS和0.5% Arg-LS水溶液摩擦试验后磨斑的三维形貌对应X和Y方向的横截面轮廓图:

(a)去离子水;(b) 0.5% Lys-LS;(c) 0.5% Arg-LS

(a1) (b1) (c1)

500 μm 500 μm 500 μm

(a2) (b2) (c2)

Middle wear

Adhesive wear

Middle wear Middle wear

Corrosion wear

20 μm 20 μm 20 μm

Fig. 7 SEM micrographs of the grinding surface of the worn spots lubricated by distilled water and Lys-LS aqueous solutions with

different mass fraction: (a) deionized water; (b) 0.5% Lys-LS; (c) 0.5% Arg-LS

图 7 去离子水、0.5% Lys-LS和0.5% Arg-LS水溶液摩擦试验后磨斑表面的SEM照片:(a)去离子水;

(b) 0.5% Lys-LS;(c) 0.5% Arg-LS