Page 20 - 《摩擦学学报》2020年第5期

P. 20

第 5 期 胡华民, 等: 横向交变载荷下TiCN/MoS 2 涂层螺栓的防松性能研究 575

表 1 M12螺栓参数 显变化,但与复合涂层螺母配合时,螺纹表面的磨损

Table 1 The parameters of M12 bolts 区域由中部转变为牙顶处,其原因是高预紧力下复合

Parameters Specification

涂层螺栓/螺母接触更紧密,而与无涂层螺母配合时螺

Minor diameter of screw thread,d 1 /mm 10.106

纹表面损伤区域未发生转变.

Pitch diameter of screw thread,d 2 /mm 10.863

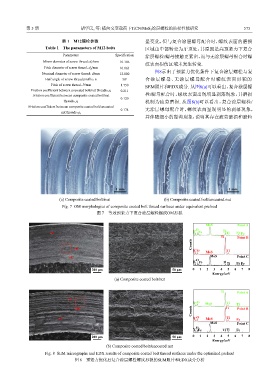

图8示出了预紧力优化条件下复合涂层螺栓与复

Nominal diameter of screw thread,d/mm 12.000

Half angle of screw thread profile,α 30° 合涂层螺母、无涂层螺母配合时螺纹表面形貌的

Pitch of screw thread,P/mm 1.750

SEM照片和EDX成分. 从图8(a)可以看出,复合涂层螺

0.211

Friction coefficient between uncoated bolt/nut threads,μ t

Friction coefficient between composite coated bolt/nut 栓/螺母配合时,螺纹表面出现明显剥落现象,其磨损

0.120

机制为疲劳磨损. 从图8(b)可以看出,复合涂层螺栓/

threads,μ t

Friction coefficient between composite coated bolt/uncoated

0.174 无涂层螺母配合时,螺纹表面呈现明显的剥落现象,

nut threads,μ t

并伴随细小的犁沟现象,说明其存在疲劳磨损和磨粒

1 mm 1 mm

(a) Composite coated bolt/nut (b) Composite coated bolt/uncoated nut

Fig. 7 OM morphologies of composite coated bolt thread surfaces under equivalent preload

图 7 等效预紧力下复合涂层螺栓螺纹OM形貌

MoS Point A

O

C Fe Ti

A Ti Fe Fe

Ti Point B

Counts

B

CO Ti

MoS

C MoS Point C

O

C Fe Ti Ti Fe Fe

200 μm 50 μm 0 1 2 3 4 5 6 7 8

Energy/keV

(a) Composite coated bolt/nut

Ti Point A

A

C O MoS Ti Ti

Counts

B Ti Point B

C C O MoS Ti Fe

MoS Point C

O

C Fe Ti Ti Fe

200 μm 50 μm 0 1 2 3 4 5 6 7 8

Energy/keV

(b) Composite coated bolt/uncoated nut

Fig. 8 SEM micrographs and EDX results of composite coated bolt thread surfaces under the optimized preload

图 8 预紧力优化后复合涂层螺栓螺纹形貌的SEM照片和EDX成分分析