Page 107 - 《摩擦学学报》2020年第4期

P. 107

第 4 期 尹艳丽, 等: 蛇纹石矿物作为润滑油添加剂对锡青铜摩擦学行为的影响 517

400 5

Unworn tin bronze surface Unworn tin bronze surface

Worn surface with base oil Worn surface with base oil

320 4

Tribofilm by serpentine oil Tribofilm by serpentine oil

Load/mN 240 Hardness/GPa 3 2

160

80 1

0 0

0 500 1 000 1 500 2 000 0 500 1 000 1 500 2 000

Depth/nm Depth/nm

(a) Load-depth curve (b) Hardness-depth curve

200

160

Modulus/GPa 120

80

Unworn tin bronze surface

40

Worn surface with base oil

Tribofilm by serpentine oil

0

0 500 1 000 1 500 2 000

Depth/nm

(c) Modulus-depth curve

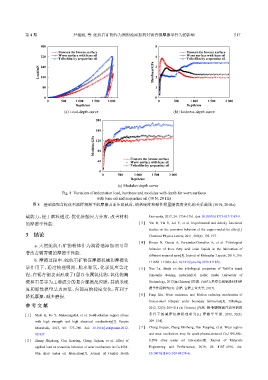

Fig. 8 Variation of indentation load, hardness and modulus with depth for worn surfaces

with base oil and serpentine oil (30 N, 20 Hz)

图 8 基础油和含蛇纹石油样润滑下的摩擦表面压痕载荷、纳米硬度和弹性模量随深度变化的关系曲线 (30 N, 20 Hz)

载能力,便于磨粒通过,优化接触应力分布,改善材料 University, 2017, 24: 1754–1761. doi: 10.1007/s11771-017-3583-9.

的摩擦学性能. [ 3 ] Yin B, Yin Y, Lei Y, et al. Experimental and density functional

studies on the corrosion behavior of the copper-nickel-tin alloy[J].

3 结论 Chemical Physics Letters, 2011, 509(4): 192–197.

[ 4 ] Rivera N, García A, Fernández-González A, et al. Tribological

a. 天然蛇纹石矿物粉体作为润滑油添加剂可显

behavior of three fatty acid ionic liquids in the lubrication of

著改善锡青铜的摩擦学性能.

different material pairs[J]. Journal of Molecular Liquids, 2019, 296:

b. 摩擦过程中,蛇纹石矿物在摩擦机械和摩擦化 111858–111869. doi: 10.1016/j.molliq.2019.111858.

学作用下,通过物理吸附、脱水释氧、化学反应等过 [ 5 ] Xue Lu. Study on the tribological properties of FeS/Cu based

程,在锡青铜表面形成了1层以金属氧化物、氧化物陶 bimetallic bearing materials[D]. Hefei: Hefei University of

瓷和石墨等为主要成分的复合摩擦反应膜,其纳米硬 Technology, 2017(in Chinese) [薛露. FeS/Cu基双金属轴承材料摩

度和弹性模量呈表面低、内部高的梯度变化,有利于 擦学性能研究[D]. 合肥: 合肥工业大学, 2017].

[ 6 ] Feng Xin. Wear resistance and friction reducing mechanism of

降低摩擦、减少磨损.

bronze-steel tribopair under boundary lubrication[J]. Tribology,

参 考 文 献

2012, 32(3): 209–214 (in Chinese) [冯欣. 钢-铜摩擦副在边界润滑

[ 1 ] Maki K, Ito Y, MatsunagahH, et al. Solid-solution copper alloys 条 件 下 的 减 摩 抗 磨 机 理 研 究 [J]. 摩 擦 学 学 报 , 2012, 32(3):

with high strength and high electrical conductivity[J]. Scripta 209–214].

Materialia, 2013, 68: 777–780. doi: 10.1016/j.scriptamat.2012. [ 7 ] Cheng Jinjuan, Zhang Shizhong, Gan Xueping, et al. Wear regime

12.027. and wear mechanism map for spark-plasma-sintered Cu-15Ni-8Sn-

[ 2 ] Zhang Shizhong, Gan Xueping, Cheng Jinjuan, et al. Effect of 0.2Nb alloy under oil lubrication[J]. Journal of Materials

applied load on transition behavior of wear mechanism in Cu-15Ni- Engineering and Performance, 2019, 28: 4187–4196. doi:

8Sn alloy under oil lubrication[J]. Journal of Central South 10.1007/s11665-019-04178-w.